Industrial Equipment

Industrial Equipment

Industrial equipment is the backbone of modern manufacturing, encompassing machinery, industrial robots, and automated systems. These tools play a crucial role in enhancing efficiency, reducing costs, and improving product quality in production processes.

Key Roles of Industrial Equipment

Enhancing Production Efficiency

Machinery and automation systems ensure continuous, precise production while minimizing operational time.

Reducing Labor Costs and Increasing Safety

Robots and machinery reduce reliance on manual labor in hazardous or labor-intensive tasks, ensuring workplace safety.

Supporting Modern Industrial Production

Technologies like IoT and AI optimize industrial equipment functionality, making them smarter and more adaptable to changing conditions.

Popular Types of Industrial Equipment

Advanced Machinery

For example, CNC (Computer Numerical Control) machines, used for cutting, drilling, and creating complex components with precision.

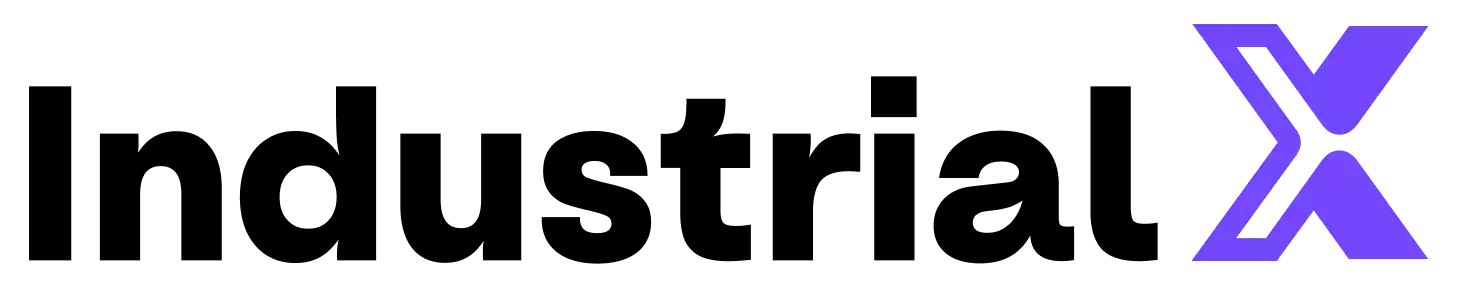

Industrial Robots

Robotic arms utilized in welding, heavy lifting, and assembly tasks on production lines.

Factory Automation Systems

Conveyor systems and automated storage and retrieval systems (ASRS) streamline operations, increasing speed and reducing errors.

Trends in the Industrial Equipment Sector

IoT (Internet of Things) Integration

IoT connects machines and devices in factories, enabling real-time data analysis and improved operational efficiency.

Energy-Efficient Technologies

Development of low-energy machinery and equipment helps reduce costs and environmental impact.

Industry 4.0 Solutions

Systems leveraging AI and Big Data to refine production processes and improve factory management.

Other Industries

Exploring Innovative Solutions